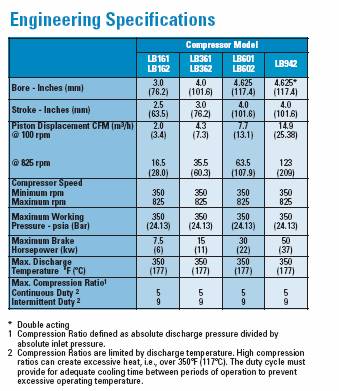

Blackmer oil-free gas compressors deliver high efficiency in handling propane, butane, anhydrous ammonia and other liquefied gases. They are ideal for rail car unloading and vapor recovery applications.

The single-stage, reciprocating compressors are designed to give maximum performance and reliability under the most severe service conditions. All pressure parts are of ductile iron construction for greater resistance to both thermal and mechanical shock.

They are designed for ease of maintenance, with all components readily accessible.

Models are available with capacities from 7 to 125 cfm (11.9 to 212 m3 /h) with working pressure up to 425 psia (29.31 Bar).